Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

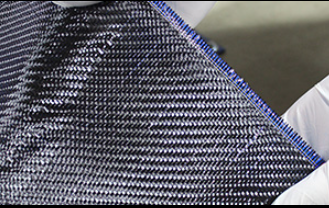

In the field of carbon fiber products have dry carbon fiber and wet carbon fiber said, this distinction is from the production process of carbon fiber products to show. At present, the two most commonly used methods of carbon fiber composite processing are prepreg autoclave molding mode and vacuum injection mode. As a result of the use of cloth in the process of infiltration is also a dry and wet embodiment, the following common carbon fiber wet molding and dry molding and the difference.

At present, the main formula of carbon fiber composite is carbon fiber and resin composite, and there are two ways to combine the two materials. In the field of carbon fiber materials, there is a resin prepreg and fiber combination of materials called preg, in the industry will use preg to process products called dry molding, other non-preg method called wet process. At present, the way of vacuum resin injection molding is the main method of wet process, and the technology of prepreg autoclave molding is the main performance of dry process.

The main step of the vacuum transfer process is to arrange the carbon fiber cloth in the preform mould (title: Mother of Industry) , and use the vacuum pressure to arrange the resin in the mould to combine with the carbon fiber, but the proportion of materials is difficult to control accurately, in the product quality accuracy (accuracy) is difficult to control. Because the prepreg is in the production of carbon fiber cloth and resin start infiltration, combined with better and high precision proportional control, after high temperature and high pressure molding, the product quality and precision higher.

There are obvious differences in the properties of the products produced by the two processes. The wet process is prone to deformation in the process and the cut-off part is prone to debonding. The adhesion between resin and fiber is poor because of contact with air, prone to oxidation and discoloration. Dry prepreg process will not appear the above-mentioned situation, but in the ultraviolet radiation prone to performance degradation. Recommended understanding: carbon fiber composites vacuum molding and autoclave molding difference

Carbon fiber products made from these two mode of production differ in weight and hardness, and are called wet carbon fiber and dry carbon fiber. Carbon fiber products refers to carbon fiber prepreg cloth as raw materials, through different processing methods, processing to meet the use requirements of the material products. Carbon fiber parts [Soft outside but rigid inside", the quality is lighter than metal aluminum, but the strength is higher than steel, and has corrosion resistance, high modulus characteristics, in defense and military industry and civil aspects are important materials. It not only has the intrinsic characteristic of carbon material, but also has the soft machinability of textile fiber. It is a new generation of reinforced fiber. In contrast to dry carbon fibers, wet carbon fibers will deform when the carbon fibers are vacuumed, and carbon fibers will be seen in the cross section, while dry carbon fibers will not.

The carbon fiber products made by dry process have good hardness and are easy to CNC machining, but the production cycle is long and not easy to mass-produce, and the production cost is high. Carbon fiber products refers to carbon fiber prepreg cloth as raw materials, through different processing methods, processing to meet the use requirements of the material products. The cost of wet forming products is lower, the production process is relatively simple, and the production efficiency of the process is higher. At present, in the production of carbon fiber, dry molding mainly in high precision (precision) , high-quality requirements of the use of the case, the wet molding is mainly in the appearance of parts, mass production time.

Threaded Hex Nylon Standoff

Anodized Aluminum Hex Standoff

Hex Aluminum Standoffs

Aluminum Hex Female Threaded Standoff

Aluminum Hex Standoff

Aluminum Round Standoff

Threaded Aluminum Standoff

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.